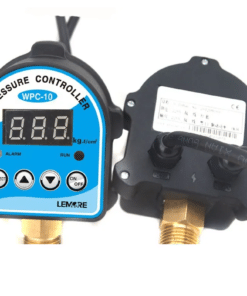

Pressure Control Switch

A pressure control switch is a device that senses pressure and activates or deactivates an electrical circuit when a certain pressure threshold is reached. It’s a crucial component in many industrial and household applications.

How it works:

- Pressure Sensing: The switch contains a pressure-sensitive element, often a diaphragm or a bellows.

- Mechanical Linkage: The pressure element is connected to a mechanical linkage that activates electrical contacts.

- Electrical Circuit Activation: When the pressure reaches the set point, the contacts close or open, triggering a specific action.

Types of Pressure Control Switches:

- Differential Pressure Switches: Monitor the pressure difference between two points.

- Pressure Limit Switches: Activate or deactivate a circuit when a specific pressure limit is reached.

- Pressure Relief Valves: Automatically release pressure when it exceeds a certain level.

Applications:

- Industrial Automation: Controlling pumps, compressors, and other equipment.

- HVAC Systems: Regulating air pressure in HVAC systems.

- Hydraulic Systems: Monitoring and controlling hydraulic pressure.

- Pneumatic Systems: Regulating air pressure in pneumatic systems.

- Automotive Systems: Controlling fuel injection systems and turbochargers.

- Household Appliances: Regulating water pressure in washing machines and dishwashers.

Key Features:

- Pressure Range: The range of pressures the switch can monitor.

- Accuracy: The precision of the pressure measurement.

- Response Time: The speed at which the switch reacts to pressure changes.

- Durability: The ability to withstand harsh environments and vibrations.

- Electrical Ratings: The voltage and current ratings of the switch’s contacts.

By understanding the principles of pressure control switches, you can effectively use them to automate processes, improve efficiency, and ensure safety in various applications.

Pressure Control Switch

Pressure Control Switch

Pressure Control Switch