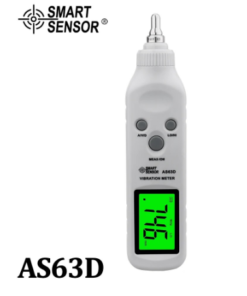

Vibration Meter

A vibration meter is a device used to measure the vibration of a machine or structure. It’s a crucial tool for predictive maintenance, as excessive vibration can indicate potential mechanical problems.

How it works:

- Sensor: A vibration sensor, typically an accelerometer, is attached to the machine or structure.

- Signal Processing: The sensor converts mechanical vibrations into electrical signals.

- Data Analysis: The electrical signals are processed to determine vibration parameters like acceleration, velocity, and displacement.

- Display: The measured vibration data is displayed on the meter’s screen, often in numerical or graphical form.

Types of Vibration Meters:

- Handheld Vibration Meters: Portable devices used for quick spot checks and routine maintenance.

- Online Vibration Monitoring Systems: Continuously monitor vibration levels and provide real-time alerts.

Applications of Vibration Meters:

- Predictive Maintenance: Early detection of machine faults.

- Quality Control: Ensuring product quality and consistency.

- Research and Development: Studying vibration phenomena and optimizing designs.

- Structural Health Monitoring: Assessing the structural integrity of buildings and bridges.

By using vibration meters, engineers and technicians can identify potential problems early on, preventing costly breakdowns and ensuring the reliability of machinery and equipment.

Vibration meter

Vibration meter

Vibration meter